Solutions Perfect for You

(Comprehensive Customization Services from Design to Performance Parameters)

As we have extensive knowledge of many industries, we can provide the perfect project solutions. No project is too big or small, and we can offer Original Equipment Manufacturing (OEM) as well as Original Design Manufacturing (ODM). What service you require will depend on your business size, needs and marketplace, and available solutions can be discussed in detail during our initial meeting.

OEM: Turning Your Designs into Added Value

Our OEM services are perfect for businesses that have a clear idea of what products they want and already have some designs in place. We will work alongside them to customize the designs and manufacture the golf carts they need when they need them. This is particularly important for fast-moving industries.

Whether you need a specific component for your production line, development of existing infrastructure, or digital signage to increase brand awareness, BAK EV has the right solution and always offers the following as standard:

- Outstanding Technical Support

- Manufacturing of Products to Spec

- High Performing Components and Systems

- Branding

- Scalable Production

ODM: Cutting Edge Design for Tomorrow

ODM is the perfect solution for businesses looking for a partner in the ideation and manufacture of a completely customized solution. Your business will provide us with a job specification, and our engineers will immediately get to work with:

- Idea Creation

- Drafting Blueprints

- Building Prototypes

- Manufacturing

- Regulatory Testing

Flexible Delivery Dates Based on Project Requirements We’ll do all of this with constant collaboration between our team and yours to ensure we deliver the product you want when you want it.

OEM/ODM Design

Solutions Perfect for You

Comprehensive Customization Services from Design to Performance Parameters

Our Promise

Full-stack Support: Design, Manufacturing, Shipping.

Communication

The communication stage is the first milestone in your ODM/OEM journey. Before meeting with BAK EV team, be sure to gather up all your project stakeholders (marketing, engineering, software, user-experience, design, sales, finance, logistics, customer service, etc) to write a Product Requirements Document (PRD).

Once your PRD is ready, you will be able to work with our professional engineers at BAK EV to create an Engineering Requirements Document (ERD). The ERD will cover the technical aspects of your product, e.g. design, components, operating environment, performance, and lifespan. Bill-of-Materials (BOM) cost and the feasibility will also be estimated during the ERD planning stage.

Initial Prototype

At this stage, feedback from all stakeholders on Prototype I is crucial. Therefore, we strongly recommend that you send your staff to our factory for on-site communication.

We will produce an initial prototype (Prototype I) and send it to you. If your product involves the industrial design (ID) of external components (such as housings or covers), please inform us in advance. We will ensure that your intellectual property and confidentiality issues are properly managed, including the protection of patents, copyrights, and confidential information.

Corrected Prototype

Prototype II hardware will undergo the previously specified qualification tests in the ERD, such as accelerated aging, performance, and driving maneuverability.

Based on the results of the qualification tests or software development, we may proceed to Stage 4 or modify Prototype II to better meet the requirements of the PRD and ERD.

Final Prototype

The final stage involves producing a final prototype (Prototype III).

Once your team is satisfied with the results, you will receive the deliverables previously agreed upon in the ERD. At the end of this stage, you can decide whether to receive your intellectual property or place an order with us and proceed to Stage 5, the manufacturing phase.

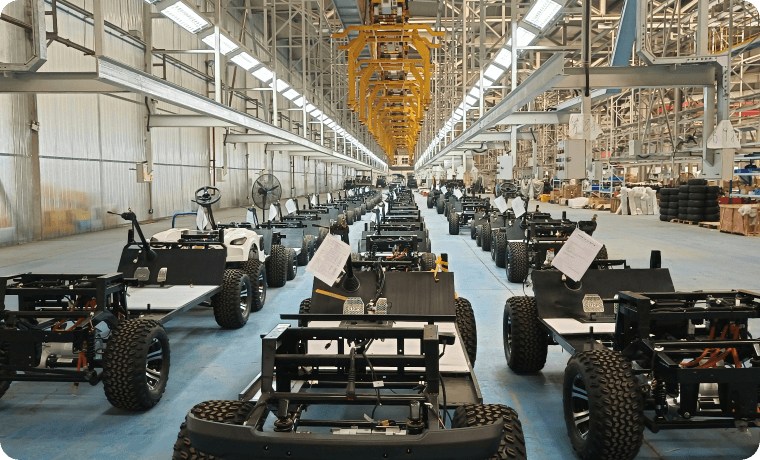

Mass Manufacturing

Once the final prototype is confirmed, you can decide whether to proceed with full production, and we can begin Stage 5. At this point, you may send your internal or third-party quality control personnel to our assembly line.

Your quality control personnel must pay attention to subjective variables such as serialization and barcoding, silk screen color printing (considering different lighting conditions between our factory and your environment), English grammar, and readability.